Industrial Ultrasonic Cleaning

Precision Cleaning of Parts with Next Generation Ultrasonic Systems

Cavitation micro-scrubbing penetrates crevices, blind holes, and intricate features—abrasion-free, reliable, repeatable.

- Non Abrasive yet Powerful

- Consistant and Precise

Get In Touch

We’re here to help—contact us for any inquiries or support you need.

What We Do

Eliminate

Rework Risk

High-frequency ultrasonics create cavitation microbubbles that collapse to remove oils, flux, oxides, and particulates—even from blind holes and deep recesses. The method is non-abrasive, material-tunable, and automation-ready, delivering consistent, repeatable cleaning across healthcare, automotive, electronics, aerospace, and other industries.

- Cavitation-driven micro-scrubbing

- Reaches crevices & blind holes

- Adjustable energy levels

- Consistent, repeatable results

Project Case Study

Project Case Study

Aviation Industry

Triple 7 Aircraft and Metal Cleaner Prevents Rust on Ultrasonic Machine Cleaned Parts.

Automotive Industry

Enhancing Cleaning Efficiency in an Auto Component Manufacturing Industry.

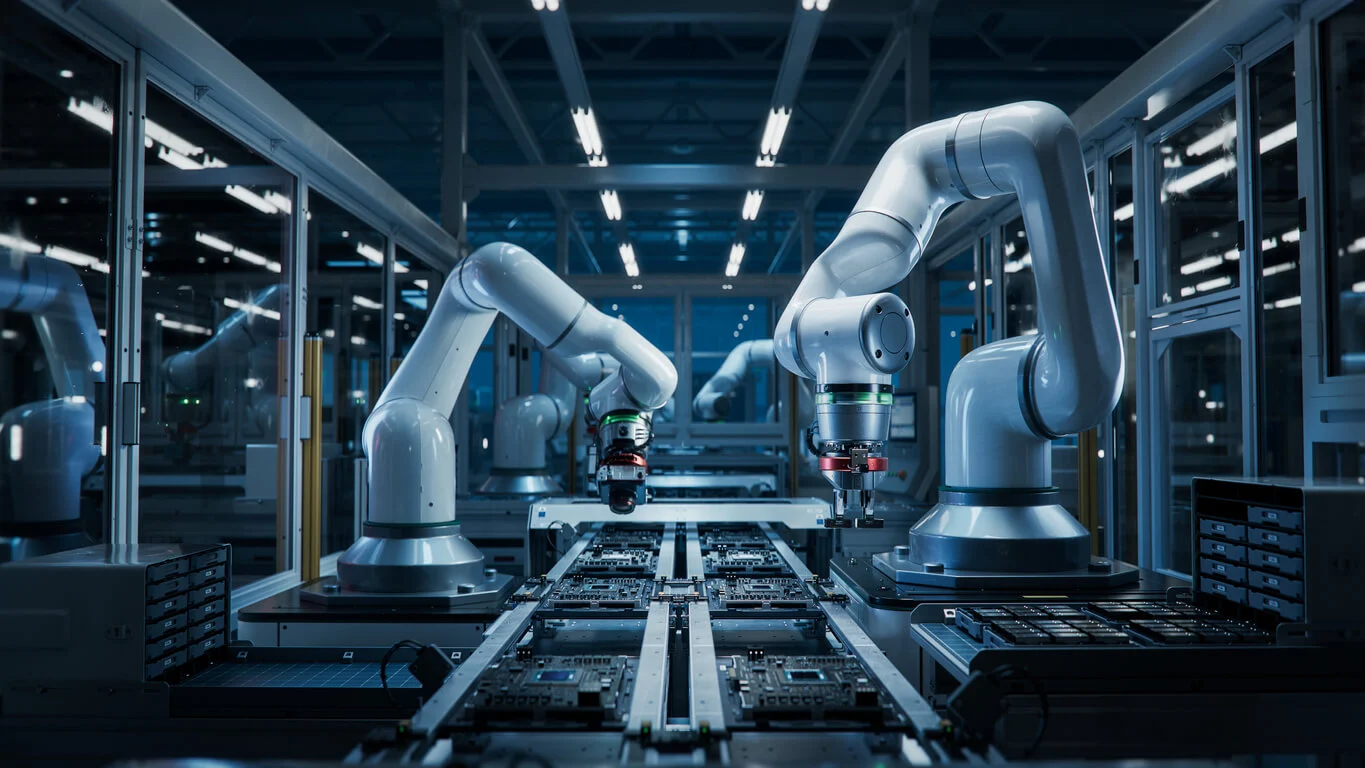

Engineering Industry

Enhancing HSS Tool Bit Coating Performance with Triple 7 Aircraft and Metal Cleaner.

Why Ultrasonic

Why Choose Precision Cleaning in Ultrasonic ?

Efficient, precise, and cost-effective cleaning—without abrasion. Ideal for delicate components and tough contaminants alike.

- User Specific Adjustable Energy

- Sub microscopic cavitation reaches every crevice

- Ideal for intricate detail, deep recess es and blind holes

- Very easy to Automate for high quality, predictable and consistent results

Our Clients

Trusted by leading brands worldwide.

Book a free cleaning study

Send us your parts — we’ll run test cycles and share a full report with photos & parameters.

Real Stories from Our Customers

Testimonial

We would like to extend our sincere appreciation to Evergreen Solutions for the timely and successful supply of the Ultra Sonic machine for the MT.DERM Medical Project. Since the date of delivery, the machine has been fully operational and is contributing significantly to the efficiency and effectiveness of our ongoing medical procedures. We acknowledge the quality of the equipment provided and commend your team for the professional coordination and support throughout the procurement and installation process. We value this partnership and look forward to continued collaboration on future projects.

We sincerely thank Evergreen Solutions for the timely supply and installation of the ultrasonic cleaner for our IT operations. The unit has been fully operational, delivering consistently clean PCBs, heatsinks, and connectors with faster turnaround and minimal rework. Your guidance on safe use made adoption simple for our team. We appreciate the quality equipment and professional support, and look forward to continued collaboration.

We sincerely thank Evergreen Solutions for the timely supply and installation of the Ultrasonic Cleaner for our automotive manufacturing operations at Ashok Leyland. The unit has been fully operational, delivering consistently clean engine components, injectors, gears, and other precision parts, resulting in faster turnaround times, improved performance, and reduced rework on the assembly line. Your team’s expert guidance on safe and efficient usage made the integration seamless for our workforce. We truly value the reliability of the equipment and the professional support provided throughout the process.

FAQ

Frequently Asked Questions

Ultrasonic transducers send high-frequency sound waves through a liquid, creating microscopic bubbles. These bubbles collapse (cavitation) and release localized energy that dislodges contaminants—even in tiny crevices—without scrubbing.

No. It’s one of the least abrasive cleaning methods. Cavitation energy removes soils while preserving the surface integrity of delicate or sensitive parts.

Yes. Cavitation occurs throughout the liquid volume, so blind holes, deep recesses, capillaries, and intricate features are effectively cleaned where manual or spray methods struggle.

Absolutely. Energy levels are programmable, allowing you to tune the process for specific materials and soils to achieve efficient, precise cleaning.

Yes. Our systems integrate with conveyors/robots and recipe-based controls to deliver predictable, consistent results while reducing manual labor and cycle variability.